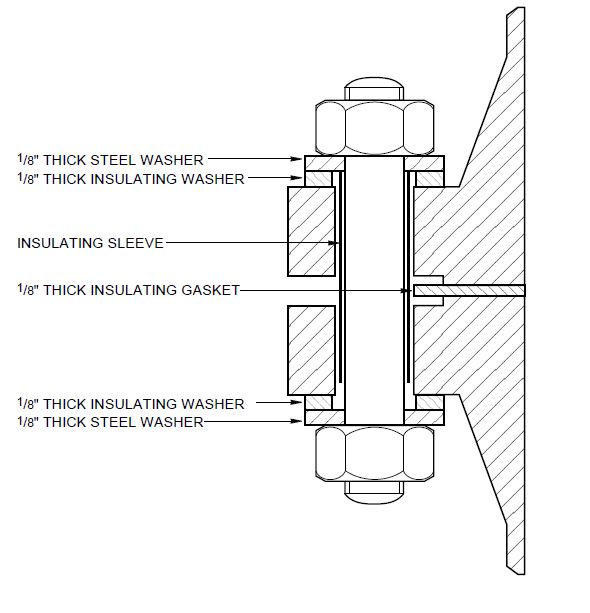

Insulating gasket kit are designed to combat the effects of corrosion often found in flanged pipe systems. Galvanic corrosion between dissimilar metal flanges (flow of currents), flange insulation associated with cathodic protection of underground piping are also the places where Insulating gasket kits are used. It consists of

Gasket Neoprene faced Phenolic /Glass Reinforced Epoxy(G10)

Insulation sleeve Reinforced Phenolic/Nylon/Polyethylene/(G10)

Insulation washer Reinforced Phenolic/ /Nylon/Polyethylene/(G10)

Plated Washer Electro plated steel washer.

What is the purpose of insulating gasket kit

Insulation kits are used to electrically insulate flanges and flanged joints in piping systems. They are typically used in applications where there is a risk of galvanic corrosion or stray currents.

When two dissimilar metals are linked in an electrolyte, such as water, galvanic corrosion occurs. The metals will react with each other, with the less noble metal corroding. This can be a problem in piping systems where there are different types of metal, such as carbon steel and stainless steel.

Stray currents are electrical currents that flow through the ground or water. They can be caused by lightning strikes, grounding systems, or other electrical equipment. Stray currents can also cause galvanic corrosion, as well as other problems such as electrical interference and sparking.

Insulation kits work by breaking the electrical connection between the flanges. This prevents galvanic corrosion and stray currents from flowing. Insulation kits typically consist of a gasket, isolation sleeves, and washers. The gasket is made of a non-conductive material, such as rubber or plastic. The isolation sleeves are placed over the bolts and nuts, and the washers are placed under the nuts. This creates an electrically insulating barrier between the flanges.

Insulation kits are an important part of corrosion prevention and electrical safety in piping systems. They are used in a variety of industries, including oil and gas, chemical, and power generation.

Benefits of using insulation kit

Prevent galvanic corrosion: Insulation kits can help to prevent galvanic corrosion by breaking the electrical connection between dissimilar metals. This is especially important in applications where there is a risk of water or other electrolytes coming into contact with the flanges.

Control stray currents: Insulation kits can help to control stray currents by breaking the electrical connection between the flanges. This can help to prevent corrosion, electrical interference, and sparking.

Improve safety: By lowering the risk of electrical shock, insulation kits can help to improve safety. This is especially important in applications where there is a risk of high voltages or high currents.

Extend the lifespan of piping systems: Insulation kits can help to extend the lifespan of piping systems by preventing corrosion and other damage. This can result in cost savings for maintenance and repairs.

If you are working on a piping system where there is a risk of galvanic corrosion or stray currents, you should consider using insulation gasket kit!. They are an effective way to protect your system and improve safety.

1 thought on “What are Insulating Gasket Kit”