A gate valve is one type of valve which is used to regulate the flow of fluids (liquids or gases) in a pipe system.. It is named “gate” valve because it has a gate-like mechanism that controls the flow by either blocking it or allowing it to pass through. The gate is moved up and down by a threaded stem, and when the gate in the open position, the fluid can flow freely through the valve. When the gate is in the closed position then the fluid is blocked from flowing through the valve.

It is the most commonly & very widely used valve in industrial piping for isolation of the flow. It is manually operated and it is not recommended for regulation of the flow. Installation of this gate valve is possible from both the ends. Hence it is bi-directional valve.

Gate valves are mostly used in applications where a high degree of flow control is required, such as in water mains, sewer pipes, and industrial piping systems. They are also used in applications where it is important to be able to completely shut off the flow of fluid, such as in fire protection systems and boilers.

Types of gate valves

There are several types of gate valves, each designed to suit different applications and operating conditions. The main types of gate valves include:

Rising Stem Gate Valves: In this type, the stem attached to the gate rises as the valve is opened, providing a visual indication of the valve position. This design allows for easy identification of whether the valve is open or closed.

Non-Rising Stem Gate Valves: In contrast to the rising stem type, the stem of a non-rising stem gate valve does not move visibly as the valve is operated. Instead, it remains inside the valve body, making it more suitable for applications where space is limited.

Solid Wedge Gate Valves: Wedge-shaped gate valves have a triangular gate that moves up and down in a wedging motion. This type of valve is typically used in applications where a high degree of sealing is required. Wedge-shaped gate valves are also more resistant to wear and tear than parallel gate valves. This type of gate valve has a solid, one-piece gate that offers robust performance and tight shutoff. It is commonly used in applications where a reliable seal is critical.

Flexible Wedge Gate Valves: The flexible wedge gate valve features a two-piece gate with a slight flexibility. This design compensates for any deformities or misalignment of the valve seats, ensuring effective sealing even in imperfect conditions.

Split Wedge Gate Valves: In this design, the wedge is split into two parts, allowing each half to move independently. This configuration enhances the valve’s ability to adapt to changing conditions and provides improved sealing.

Parallel Gate Valves: Parallel gate valves have a flat gate that slides up and down in a parallel fashion to the pipe. This type of valve is typically used in applications where a high degree of flow control is required. Parallel gate valves are also relatively easy to operate and maintain.

Knife Gate Valves: This type of gate valve has a sharp-edged gate that is particularly well-suited for handling thick and viscous fluids, slurries, or powders. It is commonly used in the mining and wastewater treatment industries.

Conduit Gate Valves: Conduit gate valves have a full-bore design, meaning the internal diameter of the valve is the same as that of the pipeline. This feature minimizes pressure drop and allows for unobstructed flow.

Oxygen Gate Valves: Oxygen gate valves are specially designed to handle oxygen and other high-purity gases. They are manufactured with materials and lubricants that are compatible with oxygen service.

The choice of gate valve type depends on the specific application, the type of fluid being controlled, the pressure and temperature requirements, and other environmental factors. Proper selection ensures optimal performance, longevity, and safety in the given system.

Function of gate valve

The function of the gate in a gate valve is to block the flow of fluid when the valve is closed. The gate is typically made of metal, and it is designed to fit snugly in the valve body. When the gate is in the closed position, the fluid cannot flow past the gate, and the valve is sealed.

Gate valves are a dependable and adaptable type of valve that are utilised in a range of applications. They are a good choice for applications where a high degree of flow control is required, and they are also a good choice for applications where it is important to be able to completely shut off the flow of fluid.

Design basis conditions for handling different fluids by Gate Valve

When dealing with potable water, wastewater, and neutral liquids, the temperature between -20°C and +70°C. The speed of flow should not exceed 5 m/s, and the pressure difference should be no more than 16 bar.

For handling gas, the temperature range should be between -20°C and +60°C. The maximum flow velocity allowed is 20 m/s, and the pressure difference can go up to 16 bar.

End Preparation Gate Valve

(a) Cast Steel valves have Flanged or Butt weld end preparation.

(b) Forged Steel valves have Socket weld or Threaded end preparation.

Design & Dimension Standard

The dimension Standard for gate valve is as follows.

API 600 For Cast Steel valves (Flanged/BW valves)

API 602 Forged Steel valves (SW/Threaded valves)

ANSI B 16.34 For Pressure & Temperature limitation & Rating

ANSI B 16.10 For face to face dimension of Flanged & BW end

API 598 For Testing of valve

Main parts of Gate valves

- Body

- Bonnet

- Internals/Trim/Wetted parts: Parts that come in direct contact with the fluid.

- Gate valve has following Internals/Trim/Wetted parts.

- Wedge / Seat Ring / Stem / Gland Bush

Pressure Class of Gate valve

For the Flanged & BW valve options, you can find ratings ranging from 150 to 2500. This gives you a large selection from which to chose based on your demands.

And if you’re specifically looking for SW or Threaded valves, we’ve got an 800 rating option available for you.

Advantage of Gate valves

- High flow capacity: Gate valves have a large opening, which allows for a high flow of fluid. This makes them a good choice for applications where a lot of fluid needs to be moved.

- Low pressure drop: Gate valves have a relatively low pressure drop, which means that there is not much loss of pressure when the valve is open. This is important in applications where the pressure of the fluid is critical.

- Easy to operate: Gate valves are relatively easy to operate, even by hand. This makes them a good choice for applications where frequent operation is required.

- Durable: Gate valves are made of durable materials, such as steel or cast iron. This makes them a good choice for applications where the valve will be subjected to wear and tear.

- Cost-effective: Gate valves are relatively inexpensive, which makes them a good choice for budget-minded applications.

- Disadvantage of Gate valve

- Cannot provide zero leakage across the wedge.

- Becomes bulky in large diameters.

- Long stroke, takes longer to open.

- Does not handle throttling applications very well, because of inadequate control characteristics.

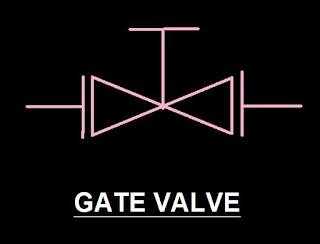

What is the gate valve Symbol

The gate valve symbol, which is represented as a rectangle with a diagonal line passing through it, is commonly used in engineering and technical drawings, especially in piping and instrumentation diagrams (P&IDs).

2 thoughts on “Gate valve function and code and material specification”